Professional Manufacturer Of High Strength Fastener

Contact Us

E-mail:

bx@bxfasteners.com

WhatsApp:

+86-13722486926

Contacts:

Manager Zhao

Phone:

+86-13722486926

Phone:

+86-17363105888

Address:

South of Hebei Pu Village, Linmingguan Town, Yongnian District, Handan City, Hebei Province

Double headed stud

- Product description

-

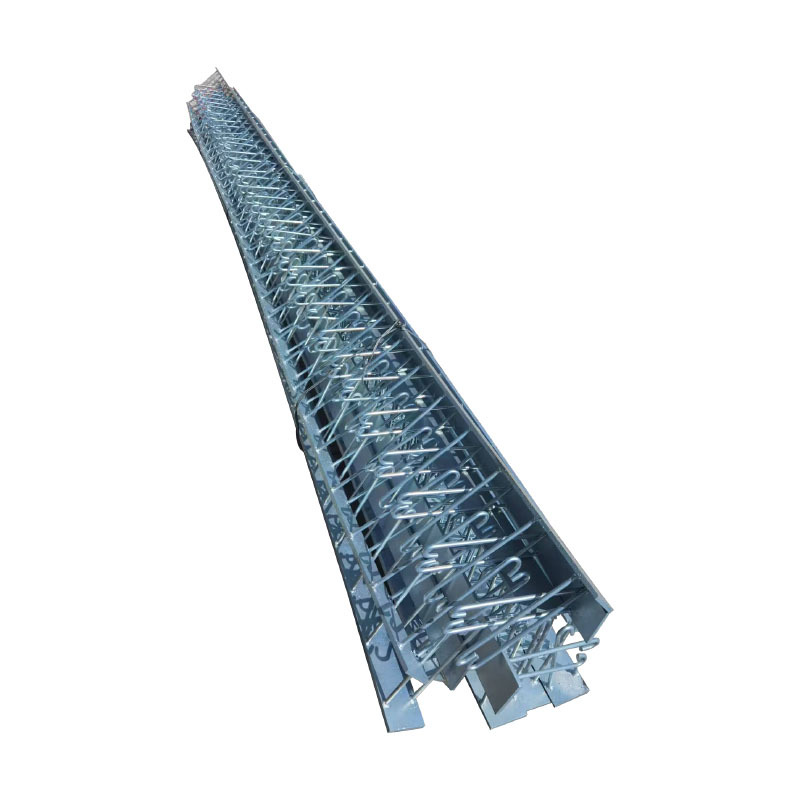

Double Headed Stud: An Ingenious Fastening Solution

In the world of engineering and construction, the choice of fasteners can significantly impact the strength, durability, and overall performance of a structure. Among various fastening solutions, the double headed stud has emerged as a versatile and effective option. This article delves into the characteristics, applications, advantages, and installation processes of double headed studs, providing a comprehensive overview of their role in modern construction and manufacturing.

Understanding Double Headed Studs

A double headed stud is a type of fastener that features two heads on either end of a threaded rod. This unique design allows for the stud to be anchored into a material from both ends, providing a secure and stable connection. The central portion of the stud is typically threaded, allowing for nuts or other components to be attached. This design is particularly advantageous in situations where space is limited, or where a secure fastening is critical.

Double headed studs are made from various materials, including stainless steel, carbon steel, and other alloys, depending on the application requirements. The choice of material often affects the stud's resistance to corrosion, temperature fluctuations, and mechanical stress.

Applications of Double Headed Studs

Double headed studs are widely used across different industries, including construction, automotive, aerospace, and manufacturing. Their ability to provide strong and reliable connections makes them ideal for various applications, such as:

1. Structural Connections: In construction, double headed studs are often used to connect beams, columns, and other structural elements. Their dual-headed design allows for efficient load distribution, ensuring the stability of the structure.

2. Equipment Mounting: In machinery and equipment installation, double headed studs facilitate the secure attachment of components. They are commonly used in heavy machinery, where vibration and movement can lead to loosening of traditional fasteners.

3. Aerospace Applications: The aerospace industry requires fasteners that can withstand extreme conditions. Double headed studs are utilized in aircraft assemblies, where their strength and reliability are crucial for safety and performance.

4. Automotive Industry: In the automotive sector, double headed studs are employed in engine components and chassis assembly, providing robust connections that can endure high levels of stress and vibration.

Advantages of Double Headed Studs

The use of double headed studs offers several advantages over traditional fasteners:

1. Increased Load-Bearing Capacity: The dual-headed design allows for a more even distribution of load, enhancing the overall strength of the connection. This makes double headed studs particularly effective in high-stress applications.

2. Space Efficiency: With two heads on either end, double headed studs require less space than conventional bolts and nuts. This is especially beneficial in compact installations where space is at a premium.

3. Ease of Installation: The installation process for double headed studs is straightforward, often requiring minimal tools. Their design allows for quicker assembly and disassembly, which can save time and labor costs in construction projects.

4. Versatility: Double headed studs can be used in a wide range of materials and applications, making them a versatile choice for engineers and builders. They can be used in various environments, from residential construction to industrial applications.

Installation Process of Double Headed Studs

Installing double headed studs involves several steps to ensure a secure and effective connection:

1. Preparation: Before installation, it is essential to prepare the materials being joined. This may involve drilling holes or ensuring that surfaces are clean and free of debris.

2. Alignment: The double headed stud should be aligned with the holes in the materials being joined. Proper alignment is crucial for achieving a secure fit and maximizing load-bearing capacity.

3. Insertion: The stud is inserted into the hole from one side, with one head resting against the surface of the first material. The second head will protrude through the hole on the opposite side.

4. Securing: Once the stud is in place, nuts can be threaded onto the exposed end of the stud. These nuts should be tightened to the manufacturer's specifications to ensure a secure connection.

5. Inspection: After installation, it is vital to inspect the connection for any signs of misalignment or inadequate tightening. Regular maintenance checks can help identify any issues before they lead to failure.

Conclusion

Double headed studs represent an innovative solution in the field of fasteners, offering numerous benefits for a variety of applications. Their unique design provides increased load-bearing capacity, space efficiency, and ease of installation, making them an attractive choice for engineers and builders alike. As industries continue to evolve and demand more robust and reliable fastening solutions, double headed studs will undoubtedly play a crucial role in the future of construction and manufacturing. Understanding their characteristics and applications will help professionals make informed decisions, ensuring the success of their projects and the safety of their structures.

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!