Professional Manufacturer Of High Strength Fastener

Contact Us

E-mail:

bx@bxfasteners.com

WhatsApp:

+86-13722486926

Contacts:

Manager Zhao

Phone:

+86-13722486926

Phone:

+86-17363105888

Address:

South of Hebei Pu Village, Linmingguan Town, Yongnian District, Handan City, Hebei Province

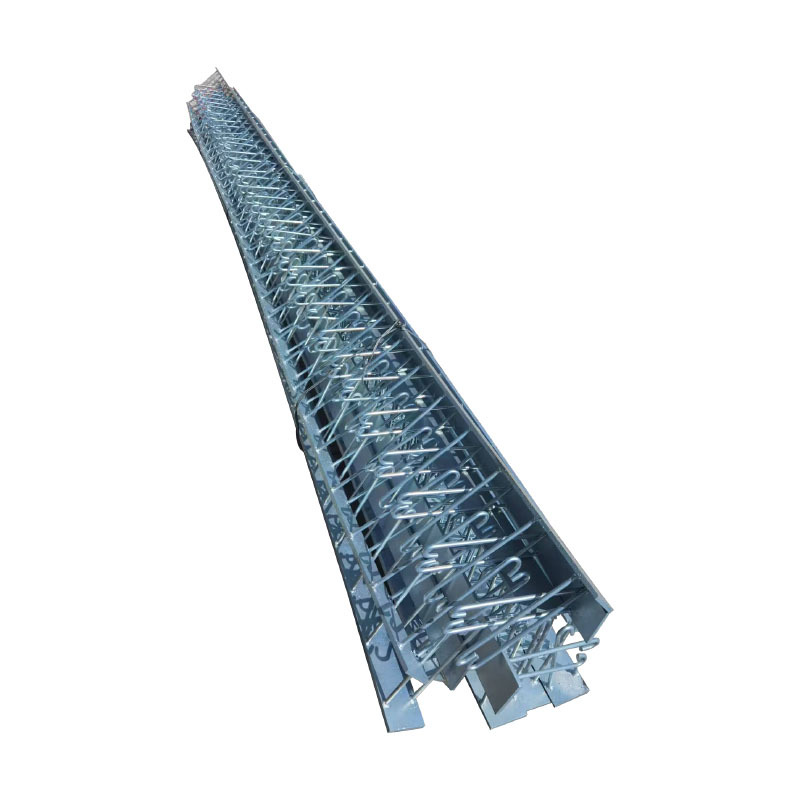

U-shaped screw

Category:

- Product description

-

The U-shaped screw is an essential component in various engineering and construction applications. Its unique design and functionality make it a popular choice for securing materials and providing structural integrity. In this article, we will explore the characteristics, applications, advantages, and potential challenges associated with U-shaped screws.

Characteristics of U-shaped Screws

U-shaped screws, as the name suggests, have a distinctive U-like shape. This design features a curved body with two straight ends that are often threaded. The curvature allows the screw to provide a more secure grip, especially when fastening materials together. The ends can be either pointed or flat, depending on the intended application.

Typically made from durable materials such as steel, stainless steel, or plastic, U-shaped screws are designed to withstand significant stress and environmental factors. Their corrosion-resistant properties make them suitable for outdoor use, while their robust construction ensures longevity and reliability.

Applications of U-shaped Screws

U-shaped screws find applications in a wide range of industries. One of the most common uses is in construction, where they are employed to secure wooden beams, metal frames, and other structural elements. Their ability to hold materials together firmly makes them invaluable in ensuring the stability of buildings and infrastructure.

In the automotive industry, U-shaped screws are used in various assemblies, such as securing components within the engine or attaching parts to the vehicle chassis. Their versatility allows them to be utilized in both light and heavy-duty applications, catering to different requirements.

Another significant application is in the manufacturing of furniture. U-shaped screws are often used to assemble pieces of furniture, providing a sturdy connection between different components. Their ease of installation and removal makes them a preferred choice for both manufacturers and consumers.

Advantages of U-shaped Screws

One of the primary advantages of U-shaped screws is their ease of use. The design allows for quick installation, often requiring minimal tools. This can significantly reduce labor time and costs in various applications, making them an efficient choice for contractors and manufacturers alike.

The U-shape also provides enhanced grip compared to traditional screws. This feature minimizes the risk of loosening over time, ensuring that materials remain securely fastened. Additionally, the curvature of the screw distributes load more evenly across the surfaces it connects, reducing the likelihood of damage to the materials.

Furthermore, U-shaped screws can be reused multiple times without losing their integrity. This characteristic not only makes them cost-effective but also promotes sustainability by reducing waste associated with disposable fasteners.

Challenges Associated with U-shaped Screws

Despite their many advantages, U-shaped screws are not without challenges. One potential issue is the need for precise alignment during installation. If not properly positioned, the screw may not provide the intended grip, leading to potential failures in the connection.

Another challenge is the compatibility with different materials. While U-shaped screws work well with various substances, some materials may require specific types of screws or fasteners to ensure optimal performance. This necessitates careful consideration when selecting the appropriate screw for a particular application.

Corrosion can also be a concern, particularly in environments exposed to moisture or chemicals. While many U-shaped screws are made from corrosion-resistant materials, it is essential to assess the specific conditions in which they will be used to avoid premature failure.

Conclusion

In conclusion, U-shaped screws are a versatile and essential component in numerous industries, offering unique advantages in terms of ease of use, grip, and sustainability. Their applications range from construction to automotive and furniture manufacturing, demonstrating their adaptability to various needs. However, users must also be aware of the potential challenges, such as alignment issues and material compatibility, to ensure successful implementation.

As technology continues to advance, it is likely that U-shaped screws will evolve as well, incorporating new materials and designs to enhance their performance. For engineers, builders, and manufacturers, understanding the characteristics and applications of U-shaped screws will remain crucial in selecting the right fasteners for their projects, ensuring safety and reliability in their work.

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!